-

Automotive Power Take OffPTO is one or more sets of variable speed gears, also known as power output device, usually by the gearbox, clutch, controller combination, with the transmission gearbox or auxiliary box output shaft connected to the power output to the external work Device.

Automotive Power Take OffPTO is one or more sets of variable speed gears, also known as power output device, usually by the gearbox, clutch, controller combination, with the transmission gearbox or auxiliary box output shaft connected to the power output to the external work Device. -

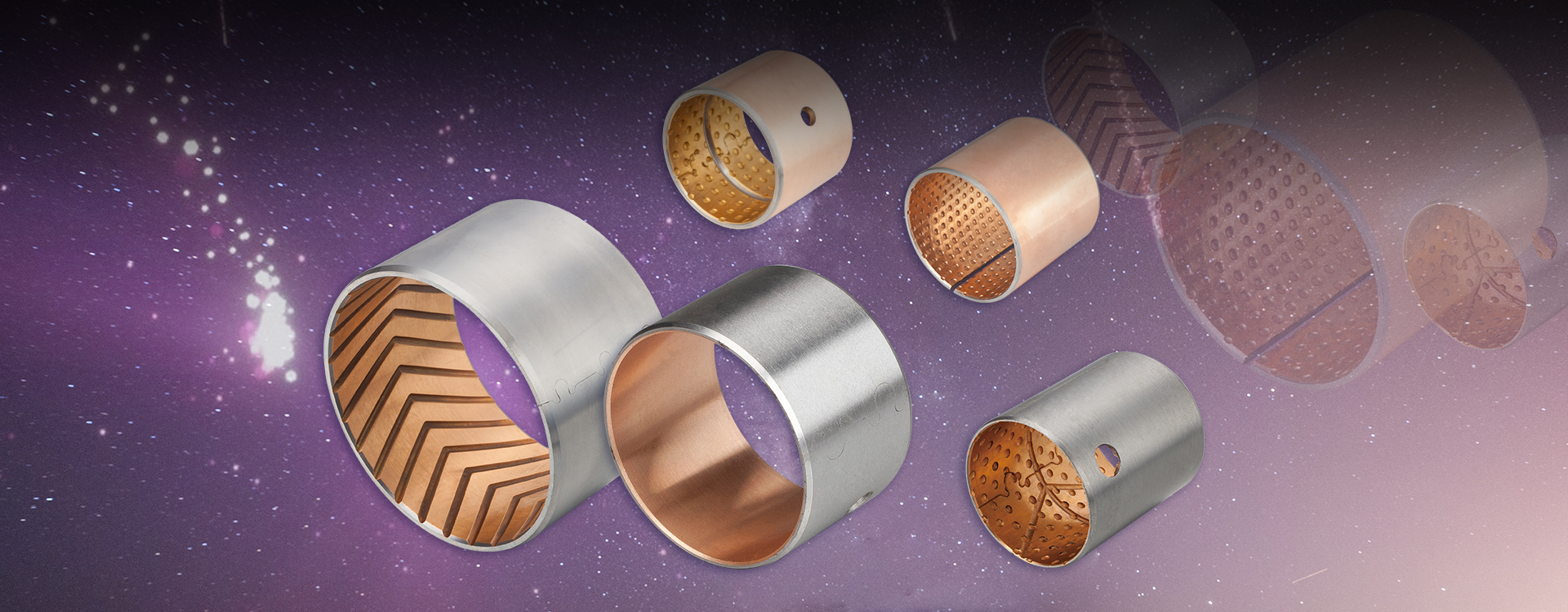

JF Bimetal BearingsJF Bimetallic bearings to high-quality low-carbon steel substrate, the surface of the sintered copper alloy having a low friction characteristics (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as...

JF Bimetal BearingsJF Bimetallic bearings to high-quality low-carbon steel substrate, the surface of the sintered copper alloy having a low friction characteristics (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as... -

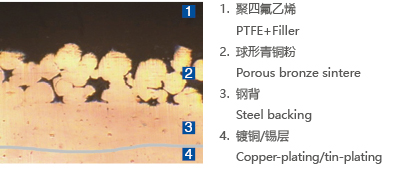

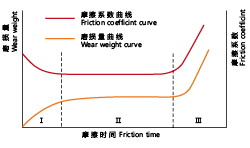

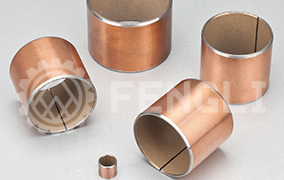

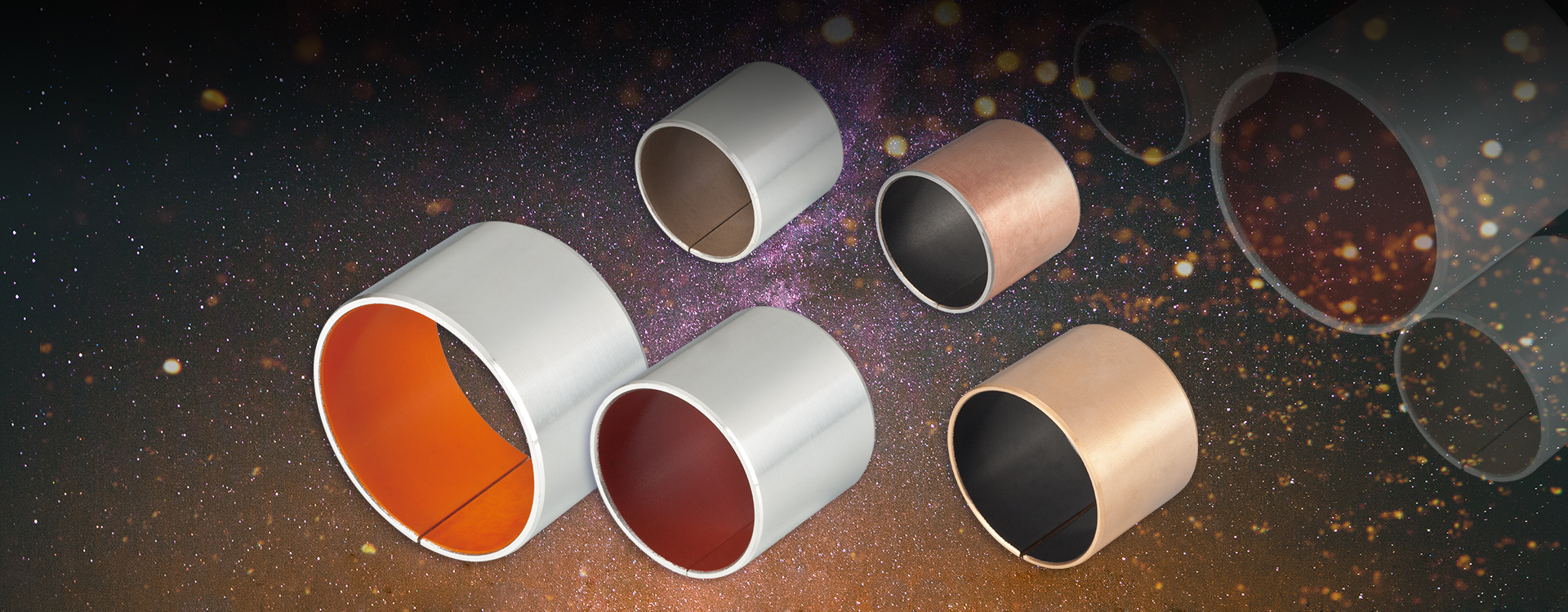

SF-1 Oilless BearingsSF-1 Oilless Bearings metal composite materials to high-quality low-carbon steel substrate, sintered porous spherical copper powder layer, the surface rolled to the PTFE-based material as a wear-resistant lubricating the bearing layer...

SF-1 Oilless BearingsSF-1 Oilless Bearings metal composite materials to high-quality low-carbon steel substrate, sintered porous spherical copper powder layer, the surface rolled to the PTFE-based material as a wear-resistant lubricating the bearing layer... -

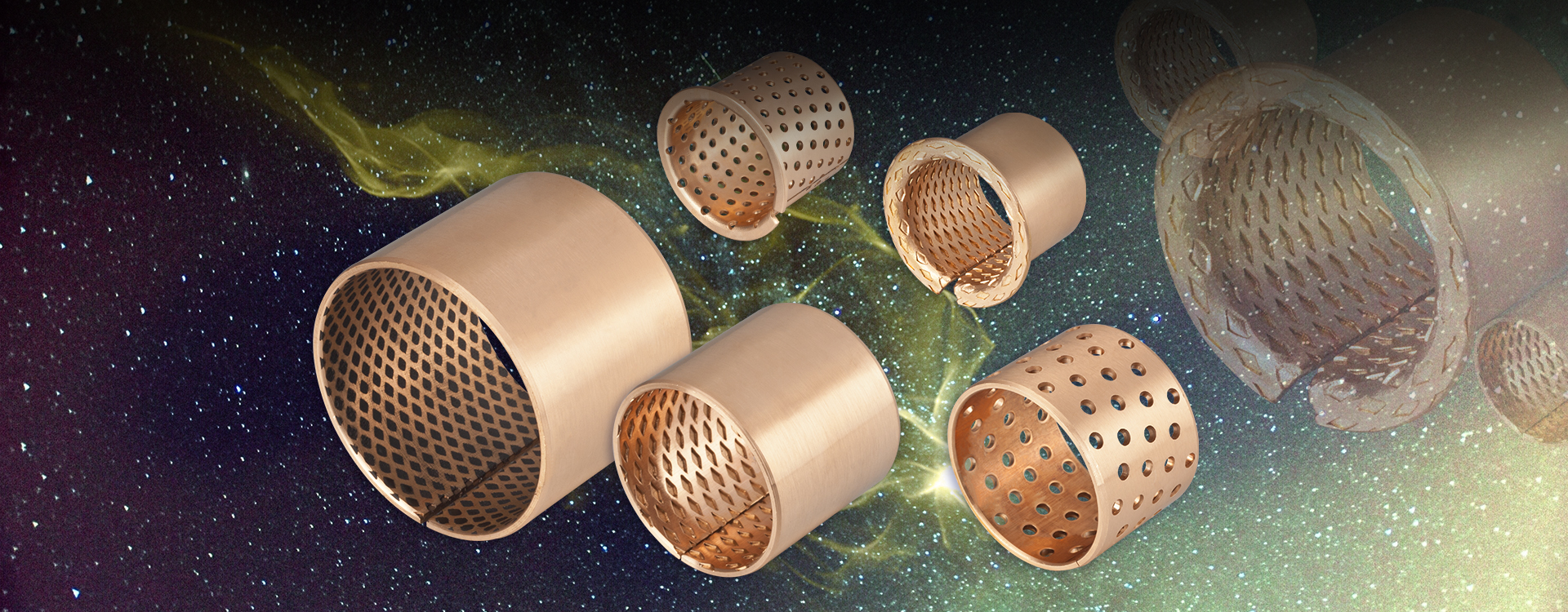

FB-090 Bronze Wrapped BushingFB-090 Bronze wrapped bushing, specially formulated high-density copper alloy strip base body surface may be requested by the user or hemispherical rolling diamond oil hole...

FB-090 Bronze Wrapped BushingFB-090 Bronze wrapped bushing, specially formulated high-density copper alloy strip base body surface may be requested by the user or hemispherical rolling diamond oil hole...